November 2025 – The European project iWAYS (Innovative Water Recovery Solutions) marks a fundamental milestone for industrial sustainability, concretely demonstrating a commitment to environmental responsibility through the implementation of large-scale resource recovery technologies in Italy, at Ceramiche Keope, a division of Atlas Concorde.

Ceramiche Keope and Unimore: 'Near-Zero Discharge' Ceramics Born with iWAYS

The company and the Emilian University collaborate to recover heat and water from exhaust fumes: a circular economy model that drastically reduces environmental impact.

The Commitment to Circularity and the Project's Origins

The iWAYS project, funded by the European Union under the Horizon 2020 program, was launched on December 1, 2020. Its central ambition is to contribute to a future where industry is responsible and green, reducing atmospheric emissions and environmental impact. The vision for iWAYS originated from an insight developed in a previous EU project (ETEKINA), when engineers noticed that Heat Pipe Heat Exchangers (HPHE) caused surprising water vapor condensation, in addition to recovering thermal energy. This realization inspired the creation of a suite of technologies capable of simultaneously recovering heat and water from waste streams.

The project was coordinated by Prof. Luca Montorsi from the University of Modena and Reggio Emilia (UNIMORE). UNIMORE's involvement was crucial in transforming an industrial challenge into a replicable solution, demonstrating that when "research and industry join forces, we can transform great challenges into real and replicable solutions."

The Technological Innovation: Effective and Robust HPCE

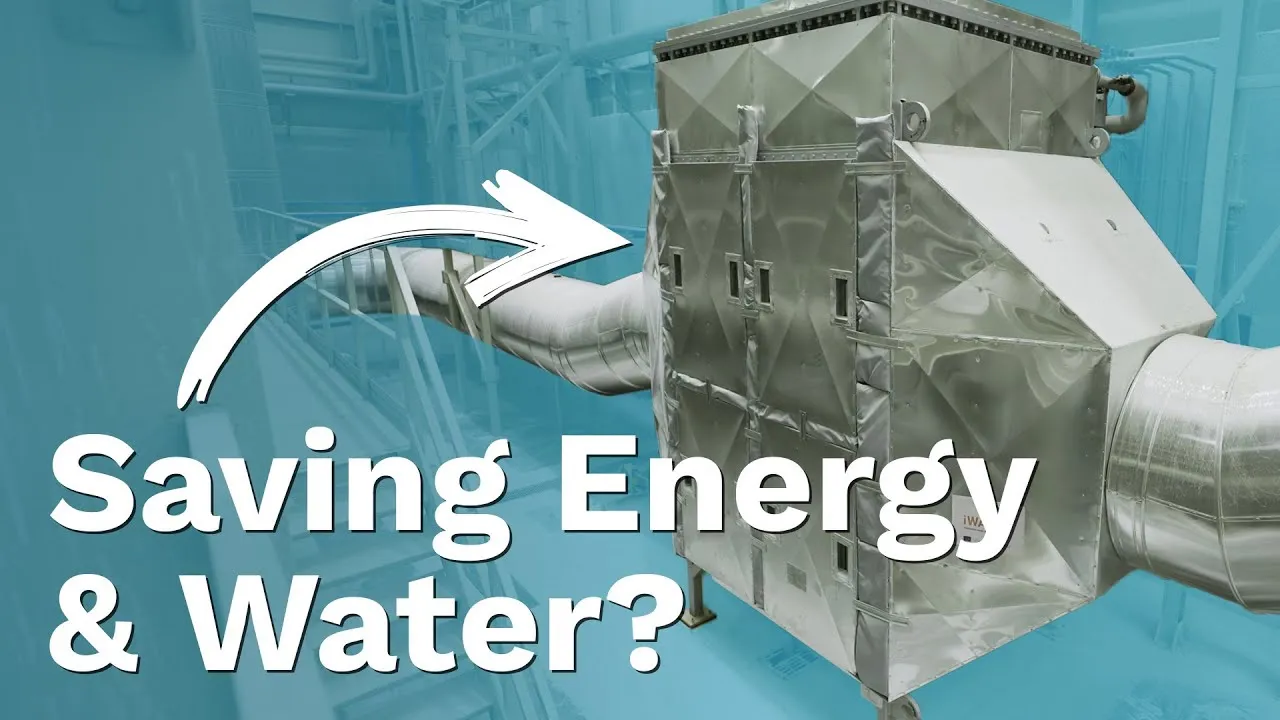

The basis of this transformation is the Heat Pipe Condensing Economiser (HPCE), a system designed to do much more than just recover heat: it transforms industrial discharge into a resource stream. The innovation in terms of responsibility is reflected in the design: the HPCE was developed to withstand acidic combustion gases, which are typical conditions in critical sectors such as ceramics.

Concrete Results at Ceramiche Keope

The success of resource recovery is tangible in the Italian ceramics sector. Ceramiche Keope installed an industrial-scale HPCE in the summer of 2025, positioning it downstream of an atomizer (spray dryer).

Heat Recovery and Energy Consumption Reduction: The HPCE captures heat from the hot exhaust gases, which is reused to preheat the air destined for the atomizer's burner.

The objective is to recover six gigawatt-hours (6 GWh) of heat annually.

This translates into a reduction in natural gas consumption of approximately 70 cubic meters per hour.

Marco Manfredini, Technical Manager at Gruppo Concorde S.p.A., highlighted that in the first months of operation, the results have been extremely positive and successful, stating that every hour of operation, the recovered energy is equivalent to that used by 20 to 30 households during the winter.

Commitment to Water Conservation: The HPCE condenses the water vapor present in the exhaust gases. The recovered water is then purified in an on-site treatment unit, which includes ultrafiltration and nanofiltration.

This combined configuration allows Ceramiche Keope to reuse clean water and reduces the consumption of freshwater.

The treated water is sufficiently pure to be reintroduced into the production cycle.

Project Conclusion: Consolidating Results in Italy

To crown the success of the installations and the validation phase, the final iWAYS project conference was held on November 19 and 20. The event brought together dozens of key stakeholders and representatives from the 19 partners across 9 countries involved in the consortium. Participants shared the encouraging results from the three critical industrial use cases (ceramic, chemical, and steel). The conference took place at the renewed headquarters of Ceramiche Keope in Italy, a key demonstration site for validating the HPCE technology in the ceramics sector.

The project coordinator, Prof. Luca Montorsi of UNIMORE, emphasized how the collaboration between research and industry has successfully transformed great challenges into real and replicable solutions. The meeting consolidated iWAYS's role in providing the European industry with the economic resilience necessary to remain competitive, maximizing resource recovery.